INDUSTRIAL WASTE FACT SHEET

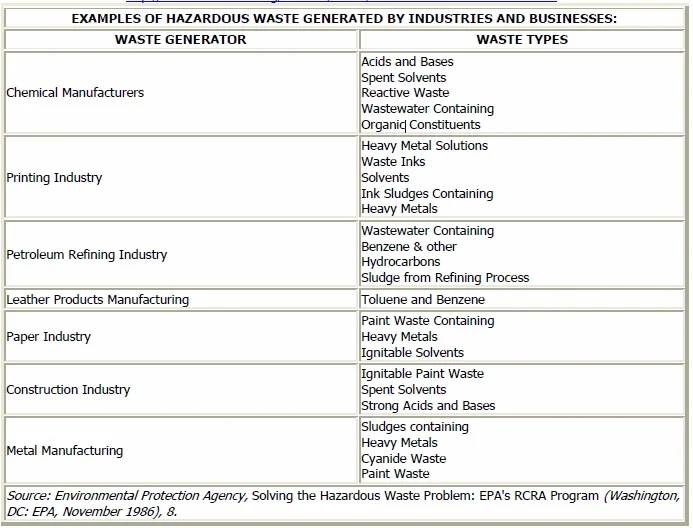

Water pollution has many sources. The most polluting of them are the city sewage and industrial waste discharged into the rivers. Industrial waste is defined as waste generated by manufacturing or industrial processes. The types of industrial waste generated include cafeteria garbage, dirt and gravel, masonry and concrete, scrap metals, trash, oil, solvents, chemicals, weed grass and trees, wood and scrap lumber, and similar wastes. Industrial solid waste - which may be solid, liquid or gases held in containers - is divided into hazardous and non-hazardous waste. Hazardous waste may result from manufacturing or other industrial processes. Certain commercial products such as cleaning fluids, paints or pesticides discarded by commercial establishments or individuals can also be defined as hazardous waste. Non-hazardous industrial wastes are those that do not meet the EPA's definition of hazardous waste - and are not municipal waste. Industrial waste has been a problem since the industrial revolution. Industrial waste may be toxic, ignitable, corrosive or reactive. If improperly managed, this waste can pose dangerous health and environmental consequences. In the United States, the amount of hazardous waste generated by manufacturing industries in the country has increased from an estimated 4.5 million tons annually after World War II to some 57 million tons by 1975. By 1990, this total had shot up to approximately 265 million tons. This waste is generated at every stage in the production process, use and disposal of manufactured products. Thus, the introduction of many new products for the home and office - computers, drugs, textiles, paints and dyes, plastics - also introduced hazardous waste, including toxic chemicals, into the environment. These, too, must be managed with extreme care to avoid adverse environmental or human health impacts. The EPA estimated in 1980 that more than 70,000 different chemicals were being manufactured in the U.S., with some 1,000 new chemicals being added each year. The human health and environmental impacts of many of these chemicals are largely unknown. High levels of toxic contaminants have been found in animals and humans, particularly those, like farm workers and oil and gas workers, who are continually exposed to such waste streams. Waste water from manufacturing or chemical processes in industries contributes to water pollution. Industrial waste water usually contains specific and readily identifiable chemical compounds. Water pollution is concentrated within a few subsectors, mainly in the form of toxic wastes and organic pollutants. Out of this a large portion can be traced to the processing of industrial chemicals and to the food products industry. Most major industries have treatment facilities for industrial effluents but this is not the case with small-scale industries, which cannot afford enormous investments in pollution control equipment as their profit margin is very slender. The effects of water pollution are not only devastating to people but also to animals, fish, and birds. Polluted water is unsuitable for drinking, recreation, agriculture, and industry. It diminishes the aesthetic quality of lakes and rivers. More seriously, contaminated water destroys aquatic life and reduces its reproductive ability. Eventually, it is a hazard to human health. Nobody can escape the effects of water pollution.

Two types of industrial waste of particular concern are dry cleaning fluids and embalming fluids. Dry cleaning fluids have contaminated groundwater supplies in all areas of the United States. One of the most common contaminants is PCE (perchloroethylene or tetrachloroethylene, Cl2C=CCl2). As a suspected carcinogen, PCE must be removed from water to very low levels. The US EPA maximum contaminant level (MCL) for PCE in drinking water is 5 ppb (5 parts per billion, or 5 mg/L). States such as New Jersey have set MCLs as low as 1 ppb for PCE in public water supplies. Cemeteries can be a source of ground water contamination caused by decaying organic matter and embalming fluids. In fact, there are several historical accounts of pollution of water wells in the vicinity of cemeteries. Embalming fluids include carcinogens. The threat of embalming fluids contaminating the water supply has prompted some cities to decrease the size of planned large cemeteries. With our aging population there is no doubt that embalming fluids will increasingly be a source of water pollution unless something changes.

Flow of Materials, Products, and Solid Waste;

Council on Environmental Quality, Executive Office of the President, Environmental Trends

(Washington, DC: Government Printing Office, July 1981), 77

http://www.texascenter.org/almanac/Waste/INDUSTRIALCH9P1.HTML#SINCE

What Can Be Done and What is Being Done?

There are many ways to reduce waste in an industrial setting. Waste minimization includes any source reduction and/or recycling activity undertaken by a waste generator (i.e. any business that produces waste through their operations). These activities result in a reduction of waste produced and/or a reduction in the toxicity of the waste. Some examples of waste minimization techniques are listed below.

Waste reduction techniques:

Change the composition of the product to reduce the amount of waste resulting from the product’s use.

Reduce or eliminate hazardous materials that enter the production process.

Use technology (including measuring and cutting) to make changes to the production process; equipment, layout or piping; or operating conditions.

Purchase what you need to avoid waste from unwanted materials.

Good operating practices such as waste minimization programs, management and personnel practices, loss prevention, and waste segregation help to reduce waste at their source.

Recycling Techniques:

Return waste material to original process.

Use the waste material as a raw material substitute for another process.

Process waste material for resource recovery.

Process waste material as a by-product.

Investigate contractors to recycle waste material.

Advertise waste material.

Use packaging waste again (cardboard, bubble wrap or polystyrene).

The term Cleaner Production was coined by the United Nations Environment Program (UNEP) when it launched the Cleaner Production Program in 1989. Cleaner Production is the continuous application of an integrated preventive environmental strategy applied to processes, products, and services to increase overall efficiency and reduce risks to humans and the environment. (UNEP, 1989).

For production processes - the strategy includes conserving raw materials and energy, eliminating toxic raw materials, and reducing the quantity and toxicity of all emissions and wastes.

For products - the strategy focuses on reducing negative impacts along the life cycle of a product, from raw materials extraction to its ultimate disposal.

For services - the strategy involves incorporating environmental concerns into designing and delivering services.

Cleaner production requires changing attitudes, responsible environmental management and evaluating technology options.

Benefits of cleaner production:Economic benefits include increased profits; improved marketability; lower expenditure on materials and resources; additional sources of income; increased quality and greater productivity; better customer service; and increased goodwill from being seen as a responsible member of the community.

Environmental benefits include less pollution; reduced production of waste; more efficient use of resources; less waste going to landfill; and less effluent to sewage or discharges to water bodies.

The Ministry of Environment in each province regulates the discharges of solid, liquid and gaseous wastes to the environment from industrial sources. They do this through developing policies and regulations using the best available science, conducting stakeholder consultations, administering the authorizations associated with discharges to the environment, and conducting compliance activities.

Technologies have been developed to solve a wide range of solid waste and other environmental and recycling problems. Many new technologies for separation and recycling of fly ash, metals, plastics, glass, sands, abrasives, automobile scrap, and plating waste sludge have been developed.

The Safe Drinking Water Foundation has educational programs that can supplement the information found in this fact sheet. Operation Water Drop looks at the chemical contaminants that are found in water; it is designed for a science class. Operation Water Flow looks at how water is used, where it comes from and how much it costs; it has lessons that are designed for Social Studies, Math, Biology, Chemistry and Science classes. Operation Water Spirit presents a First Nations perspective of water and the surrounding issues; it is designed for Native Studies or Social Studies classes. Operation Water Health looks at common health issues surrounding drinking water in Canada and around the world and is designed for a Health, Science and Social Studies collaboration. Operation Water Pollution focuses on how water pollution occurs and how it is cleaned up and has been designed for a Science and Social Studies collaboration. To access more information on these and other educational activities, as well as additional fact sheets, visit the Safe Drinking Water Foundation website at www.safewater.org.

Did you know that our Operation Water Pollution program teaches students about what water pollution is, what causes it, how it cleaned up, and what they can do about the problem? Please help us to send more Operation Water Pollution kits to schools! Please chip in $5 or donate $20 or more and receive an Official Donation Receipt for Income Tax Purposes - or donate $170 to provide an Operation Water Pollution kit for a school, it will be guaranteed to be reusable for at least two years.

Resources:

British Columbia Ministry of Environment. Industrial Waste.

http://www2.gov.bc.ca/gov/content/environment/waste-management/industrial-waste

Environmental Expert. 3.5’ LANPAC Proven Superior for Removing PCE from Groundwater in Packed Tower Air Strippers.

https://www.environmental-expert.com/articles/3-5-lanpac-proven-superior-for-removing-pce-from-groundwater-in-packed-tower-air-strippers-7413

Environmental Protection Agency. November, 1986. Solving the Hazardous Waste Problem: EPA's RCRA Program.

Texas Environmental Center. Industrial Waste: Chapter Nine.

http://www.texascenter.org/almanac/Waste/INDUSTRIALCH9P1.HTML#SINCE